Armored Control Cable Ensuring Reliable Communication and Control in Harsh Environments

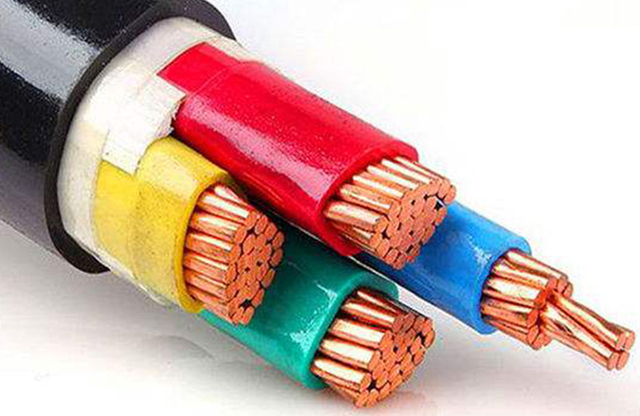

Introduction In the world of industrial automation, communication and control systems play a crucial role in ensuring the efficient operation of machinery and equipment. Armored control cables are essential components that provide a robust and reliable means of transmitting signals and power in harsh environments. These cables are designed to withstand extreme conditions such as high temperatures, moisture, and mechanical stress, making them ideal for use in a wide range of applications across various industries. In this article, we will explore the key features, benefits, and applications of armored control cables, as well as the factors to consider when selecting the right cable for your specific needs. 1. What are Armored Control Cables? Armored control cables are specially designed cables that are constructed with additional layers of protection to enhance their durability and resistance to external factors. These cables typically consist of a core conductor, insulation layer, shielding, and an outer armor layer. The armor layer is made of materials such as steel or aluminum, which provide mechanical strength and protection against physical damage. The primary purpose of the armor layer in control cables is to protect the internal components from moisture, chemicals, abrasion, and other environmental factors that could compromise the cable's performance. The armor also helps to shield the cable from electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring reliable signal transmission in noisy industrial environments. 2. Types of Armored Control Cables There are several types of armored control cables available in the market, each designed for specific applications and environmental conditions. Some of the common types of armored control cables include: – Steel Wire Armored (SWA) Cables: These cables feature a steel wire armor layer that provides excellent mechanical protection against crushing, impact, and abrasion. SWA cables are commonly used in underground installations, industrial plants, and outdoor applications where the cable is exposed to harsh conditions. – Aluminum Interlocked Armor (AIA) Cables: AIA cables consist of interlocked aluminum armor strands that offer lightweight yet durable protection. These cables are suitable for use in indoor installations, cable trays, and conduit systems where flexibility and ease of installation are important. – Steel Tape Armored (STA) Cables: STA cables are constructed with a helically-wrapped steel tape armor layer that provides high tensile strength and resistance to crushing forces. These cables are ideal for use in vertical installations, risers, and areas with limited space. 3. Benefits of Armored Control Cables Armored control cables offer a range of benefits that make them a preferred choice for critical communication and control applications. https://www.jiangyuancables.com/waterproof-rubber-sheathed-flexible-cable/ of the key benefits of armored control cables include: – Enhanced Durability: The armor layer in armored control cables provides robust protection against physical damage, moisture, chemicals, and other environmental factors, ensuring long-term reliability and performance. – Increased Safety: Armored control cables are designed to meet stringent safety standards and regulations, making them suitable for use in hazardous locations and critical systems where safety is paramount. – Excellent Signal Integrity: The shielding properties of armored control cables help to minimize electromagnetic interference and signal loss, ensuring clear and reliable communication between devices. – Versatile Applications: Armored control cables can be used in a wide range of applications, including industrial automation, power distribution, telecommunications, and transportation systems, making them a versatile solution for various industries. 4. Applications of Armored Control Cables Armored control cables find applications in diverse industries and environments where reliable communication and control are essential. Some of the common applications of armored control cables include: – Oil and Gas Industry: Armored control cables are used in offshore drilling rigs, refineries, and petrochemical plants to provide reliable communication and control of equipment in harsh and hazardous environments. – Mining and Quarrying: Armored control cables are deployed in mining operations to connect sensors, actuators, and control devices in underground tunnels, open pits, and processing plants. – Manufacturing and Automation: Armored control cables are essential in manufacturing facilities, assembly lines, and robotic systems where precise control and communication are required to optimize production processes. – Transportation and Infrastructure: Armored control cables are utilized in railways, airports, tunnels, and bridges to ensure safe and efficient operation of signaling systems, lighting, and control circuits. 5. Factors to Consider When Selecting Armored Control Cables When choosing armored control cables for a specific application, it is important to consider several factors to ensure optimal performance and reliability. Some of the key factors to consider include: – Environmental Conditions: Evaluate the temperature range, moisture levels, chemical exposure, and mechanical stress in the installation environment to select a cable with the appropriate armor and insulation properties. – Electrical Requirements: Determine the voltage rating, current carrying capacity, and signal transmission requirements of the control cable to ensure compatibility with the equipment and systems it will be connected to. – Installation Method: Consider the installation method, bending radius, and cable routing requirements to choose a cable that can be easily installed and maintained in the desired location. – Regulatory Compliance: Ensure that the armored control cable meets relevant industry standards, safety regulations, and certification requirements to guarantee its performance and reliability in critical applications. Conclusion Armored control cables are essential components that play a vital role in ensuring reliable communication and control in industrial automation and infrastructure systems. With their robust construction, durability, and resistance to external factors, armored control cables offer a dependable solution for transmitting signals and power in harsh environments. By understanding the key features, benefits, applications, and selection criteria of armored control cables, engineers and system integrators can make informed decisions when choosing the right cable for their specific needs. Whether used in oil and gas facilities, mining operations, manufacturing plants, or transportation systems, armored control cables provide a reliable and efficient means of communication and control in a wide range of industrial applications.